Partner with EnGenius Metals for Reliable Casting Solutions

At EnGenius Metals Pvt. Ltd., our foundry is an exclusive shell moulding facility specializing in critical castings, complex metallurgy, and precision machining support. With an installed capacity of 600+ MT/month, ISO 9001:2015 certification, and a global customer base, we are positioned as one of the most trusted precision cast iron foundries in Kolhapur, India.

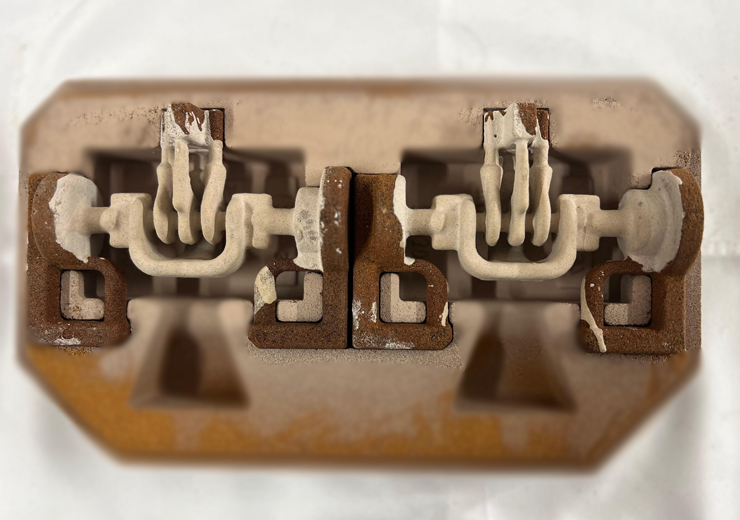

Unlike conventional multi-process foundries, we focus 100% on shell moulding, enabling us to deliver cleaner surfaces, sharper edges, and defect-free internal cavities—ideal for hydraulic manifolds, high-pressure castings, and complex industrial components.

Our Specialities

Exclusive shell moulding focus

Precision, consistency, and repeatability

SG Iron metal patterns only

High accuracy, long life, and stable production

Special metallurgy expertise

SG 400/12, 500/7, 700/3, 700/7, 400/22, ADI, CGI, SiMo, and Grey Iron grades

Imported specialty sands (Cerabid, Cromid)

For superior finish and dimensional control

Special paints for critical centre cores

Ensuring soundness and defect-free castings

Imported alloying metals

Guaranteeing strength and metallurgical integrity

Nozzle blasting machine

Deep internal cavity cleaning

Borescopic inspection of every casting

Ensuring internal cleanliness and reliability

Sand reclamation system

Eco-friendly, cost-efficient, and aligned with sustainability

Partner machining ecosystem

CNC, VMC, washing, Millipore testing, contracer, grinding, and CMM validation for ready-to-use castings

Our Machinery & Infrastructure

Melting & Metallurgy

- Inductotherm IGBT Induction Furnaces (550 kW / 500 kg)

- Shimadzu Spectrometer with real-time display in melting area – instant OK / Not-OK status for every heat

- CE meter, carbon-silicon analyzers for process monitoring

- Imported alloying metals for guaranteed strength and soundness

Moulding & Core Making

- Fully automatic shell moulding lines

- In-house core shooters (horizontal & vertical)

- Resin-coated sand prepared at partner unit for consistency and scalability

- Imported sands (Cerabid, Cromid) for special applications requiring thermal stability and finish

- Special core paints for critical centre cores

- Sand reclamation system to recycle waste sand – commitment to environment & sustainability

Fettling & Cleaning

- Cutter grinders and pedestal grinders for gating removal

- Nozzle blasting machine for precise internal cavity cleaning

- Tumble blast shot blasting machines for bulk parts

- Hanger type shot blasting machines for larger and complex castings

Inspection & Testing

- Non-Destructive testing such as Casting Radioscopy/ X-Ray

- 100% borescopic inspection of internal cavities

- Coordinate Measuring Machine (CMM) for dimensional accuracy

- Hardness testers, metallurgical microscopes, microstructure analysis, image analyzers

- Shimadzu spectrometer for chemistry validation

- PPAP, SPC, and traceability systems

Finishing & Dispatch

- VCI coatings, rust-preventive oils, and protective packaging

- Export-grade seaworthy pallets

- Strategic location: Kagal Five Star MIDC, Kolhapur, with seamless access to JNPT, Mundra, Kandla, Goa ports and Kolhapur/Pune airports for domestic & international dispatch